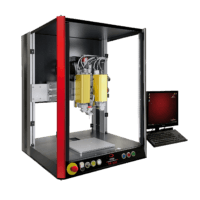

Robotics for soldering ⋅ dispensing

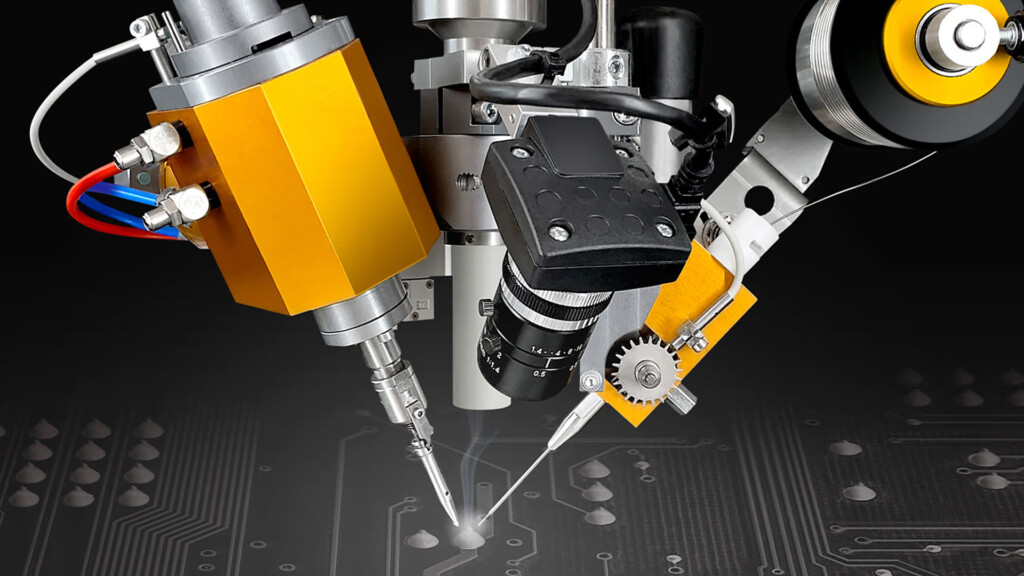

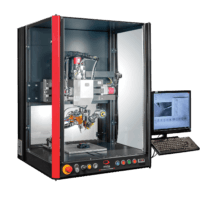

Soldering products

The soldering product range includes standalone soldering heads, manual systems, semi-automated table-top robots to fully automated productions cells and a wide range of spare parts.

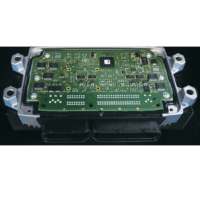

Typical soldering applications

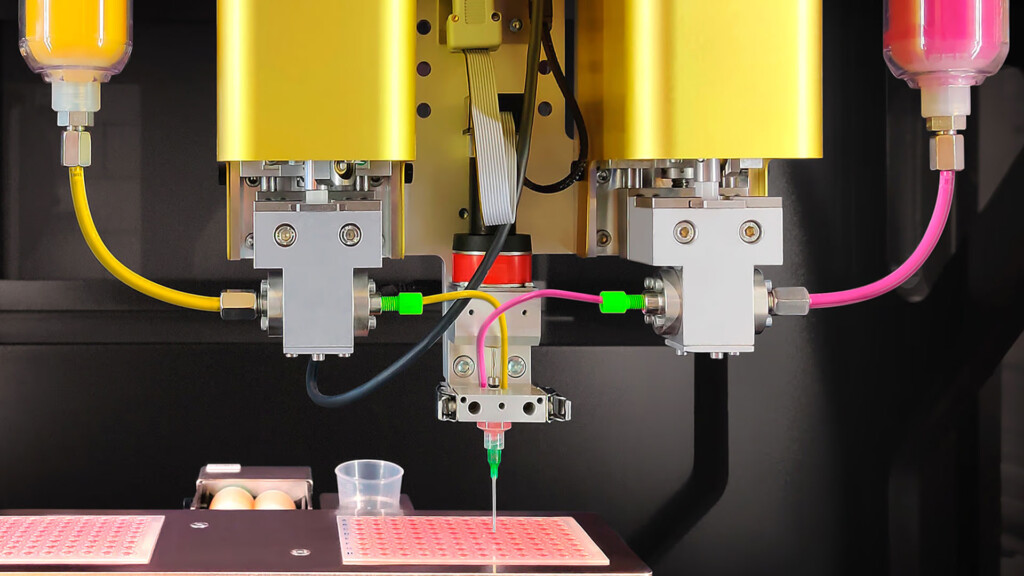

Dispensing products

The dispensing product range includes standalone dispensers, manual systems, semi-automated table-top robots to fully automated productions cells and a wide range of spare parts.

Typical dispensing applications

Selective soldering solutions

mta robotics traces its origins to the watch-making industry in Switzerland over 50 years ago. We are a leader in robotic soldering because our rich history stems from a culture of precision and reliability.

We started making soldering robots in the mid-‘80s. Our product development engineers leverage this culture to design machines that meet stringent uptime requirements. They design machines flexible enough to fulfill a wide range of applications. Then, they standardize the designs to keep costs down.

Similarly, our process development engineers have tested tens of thousands of solder joints on nearly every product imaginable. They use this wealth of experience to select technologies and develop processes optimized to provide the highest quality and solder joints and maximum yield.

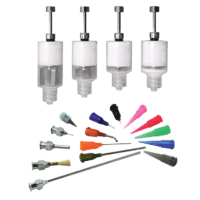

Volumetric dispensing solutions

Volumetric dispensing systems are both mechanically defined and numerically controlled to precisely control the volume and rate of material dispensed.

This is different from time-pressure systems in which the dose volume can fluctuate depending on many variables such temperature, viscosity, time i.e. pot life, air volume and system pressures.

mta robotics offers two primary technologies for volumetric dispensing, reciprocating piston pumps and continuous flow progressive cavity pumps. Between the two technologies, we can provide solutions for a broad range of materials; mono-or two-component materials, in a variety of dispensing processes including adhesive bonding, sealing, potting and conformal coating.

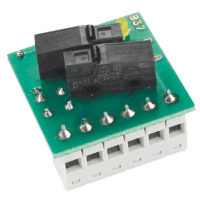

Process validation

We focus on high-quality applications and relies on the expertise of highly-qualified specialists to conduct in-depth tests in our laboratories.

These experts assess the appropriate soldering or dispensing method for each individual application resulting in a process validation.

The customer benefits by receiving a proof of process.